-

HTV挤出型高温管-內纤外胶管 ISOTEX ISOSTD

-

HTV挤出型高温管 硅胶波纹管 ISOFLEX, ISOKNIT

-

HTV挤出型內纤外胶扩张管 ULTRAFLEX ISOULTRA

-

新能源汽车线束保护 耐撞击保护管 ARA TEXFLEX DUO L

-

编织网管-EXPANDEX PET

-

编织网管-尼龙 EXPANDEX PA66

-

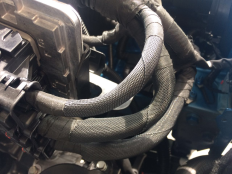

自卷管-耐摩擦保护 FLEXTEX / KMG TWIST

-

硅树脂玻璃纤维套管 ISOTEX LSI

-

热反射管-硅橡胶+铝粉 ISOTEX 300R

-

热反射管-铝箔玻纤自卷管 KMGAluWrap1463

-

硅橡胶管

-

热反射管-铝箔 ALUTEX

-

高温管

-

陶瓷化硅胶防火管

-

耐油套管

自卷管-耐摩擦保护 FLEXTEX/ KMG TWIST

新能源汽车行业

E-mobility / hybrid

新能源汽车线束保护 电动/混动

Cable manufacture

新能源汽车线束制造

Machinery and plant engineering

机械和安装工程

Key properties 主要特性

- Long-term heat resistance of -50°C to +150°C

- 长期工作温度 -50°C to +150°C

- short-term heat resistance up to +180°C

- 短期耐温可达+180°C

- Abrasion classification E, standard LV 312-3

- 耐摩擦等级 D, 根据 LV 312-1 标准, 耐磨5000次以上

- High bending and tensile strength

- 易弯折,抗拉伸

- Physiologically harmless

- 环保无害

- Nominal diameter 5.0 mm to 50.0 mm

- 内径 5.0 mm to 50.0 mm

- Colour: orange or black

- 颜色:橙色或者黑色

Product description 产品描述

FLEXTEX是一种柔性的PET保护套,用于后续装配。机织PET设计的柔韧性和弹性以及优良的耐磨效果。FLEXTEX适用于电缆和线路的绑扎,特别适用于机械保护。重叠的纵向狭缝允许在已经安装的电缆上轻松组装。组装FLEXTEX时,套筒在搭接处打开,然后推到需要保护的产品上。FLEXTEX可以很容易地在整个长度内组装和拆卸。大量的应用程序不需要任何额外的修正。许多应用不需要额外的固定,但如果有必要,可以使用电缆扎带或软管夹。FLEXTEX也有自粘版(FLEXTEX SK,用于固定封闭性)。

FLEXTEX is a flexible PET protective sleeve for subsequent assembly. The flexibility and resilient behavior with excellent abrasion resistance results of the woven PET design. FLEXTEX is suitable for bundling cables and lines, especially for mechanical protection because of the properties. The overlapping longitudinal slit alows an easy assembly on already installed cables. To assemble FLEXTEX, the sleeve is opend at the lap and it is pushed over the product which has to be protected. FLEXTEX can easily be assembled in the entire length as well as disassembled again. A large number of applications do not require any additional fixing. A lot of applications do not need an additional fixation but if it is necessary cable ties or hose clamps can be used. FLEXTEX is also available in a self-adhesive version (FLEXTEX SK, for fixing the closure).

Application properties 应用性能

|

Property 性能 |

Standard 标准 |

Test requirements 测试要求 |

Result 结果 |

|

Flame resistance 阻燃性能 |

LV312-2 FMVSS 302 |

Flame exposure 15s Sample location closed 燃烧15S |

Classification C C级 |

|

Shrinkage 收缩性 |

ISO 6722-1 |

Temperature 205°C 温度205°C |

Requirement achieved |

Aging 老化性能

|

Property 性能 |

Standard 标准 |

Test requirements 测试要求 |

Result 结果 |

|

Hydrolysis test 水解测试 |

LV 312-3 |

1500h at 85°C 85°C 1500 小 时 85% relative humidity 85% 相对湿度 Winding test at room temperature 在室温做卷绕测试 |

Requirements achieved 达到要求 |

|

Short-term ageing 240h / 205°C 短期老化 240h / 205°C |

LV 312-3 ISO 6722-1 |

Winding test under standard conditions 标准条件下卷绕实验 |

Requirements achieved 达到要求 |

|

Short-term ageing 375h / 210°C 长期老化 375h / 210°C |

LV 312-3 |

Winding test under standard conditions 标准条件下卷绕实验 |

Requirements achieved 达到要求 |

|

Long-term ageing 3000h / 180°C 长期老化 3000h / 180°C |

LV 312-3 ISO 6722-1 |

Winding test under standard conditions 标准条件下卷绕实验 |

Requirements achieved 达到要求 |

|

Temperature and humidity cycling 温湿度循环 |

ISO 6722-1 |

-40°C to + 175°C Humidity: 80-100% Cycles: 40 温 度 -40°C to + 175°C 湿度:80-100% 循环: 40 |

Requirements achieved 达到要求 |

Mechanical / physical properties机械/物理性能

|

Property 性能 |

Standard 标准 |

Test requirements 测试要求 |

Result 结果 |

|

Abrasion resistance 耐磨性 |

LV 312-1 |

Temperature 23°C 温度 23°C frequency: 8 Hz 频率 8Hz power: 7 N 拉 力 7 N |

Classification D 等级 D |

标准尺寸

Standard dimensions

|

ID [mm] |

Tol. ID [mm] |

Wd [mm] |

Tol. Wd [mm] |

Ring [m] |

|

5.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

8.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

10.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

13.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

16.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

18.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

19.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

25.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

29.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

32.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

35.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |

|

50.0 |

overlapping 90°+40°-25° |

0.60 |

±0.25 |

production length on customer specification |